Frequency-controlled hot water station. High-pressure hot water stations for professional machines.

Farmers and subcontractors invest enormous amounts in their machine parks. Careful maintenance does not only help to preserve these investments, but also guarantees the operational safety of machines and accessories.

Our frequency controlled hot-water stations provide the perfect solution for daily cleaning of valuable machinery of farmers, subcontractors, slaughterhouses and operations with large vehicle fleets such as municipalities and forwarders.

Well-kept machines for long-lasting use.

On request our specialists install the high-pressure hot-water station directly inside the engineering room. It captivates with its extremely high water output und heating capacity. Water volume, operating pressure, number of users, water temperature and detergents for foam pre-cleaning are freely selectable.

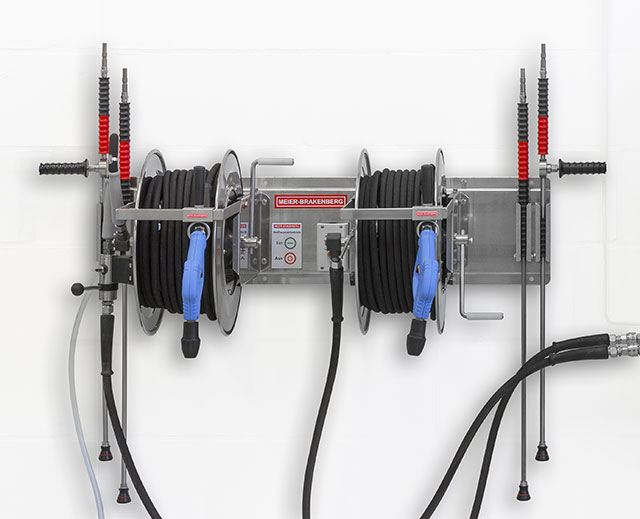

Practical installation of the hose and lance station directly at the washing station. The frequency controlled pump provides flexible amounts of water of up to 4,200 l/h and facilitates cleaning e.g. of a tractor with 20 l/min and 70 °C hot water while at the same time someone else cleans heavily soiled equipment with 50 l/min of cold water. Suitable cleaning power and flexible water temperature for each application.

The strengths of frequency-controlled hot-water stations.

- Frequency-controlled high-pressure aggregate for up to 3,000 l/h or 4,200 l/h

- Hot-water unit infinitely variable for up to 90 °C

- Spatial separation of high-pressure pump station and lance unit with hose drum panel at washing station

- Pressure-control lance with infinitely variable pressure adjustment

- Addition of detergents via integrated injector

- Intensive foam cleaning possible

- Large-volume 3 cylinder plunger pump with crank shaft drive and ceramic pistons

- Connection of electric motor and pump by claw coupling with rubber dampers for optimum power transmission

- Smooth change of rotational speed for long service life

Product Details

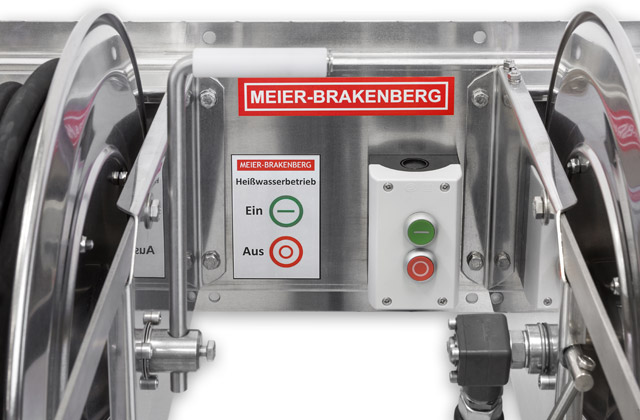

High-pressure technology - Control elements at hose drum panel

Intuitive control elements at the hose drum panel allow the control of subcontractor unit from washing station.

High-pressure technology - Injector at hose drum panel

The high-pressure injector at the hose drum panel facilitates easy and fast metering of detergents and disinfectants during machine cleaning.

High-pressure technology - Large volume piston pump

Professional high-pressure pump with ceramic pistons and brass piston rods - guarantees endurance and long service life.

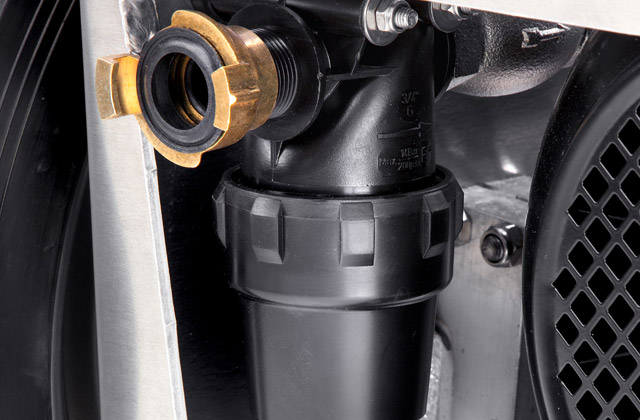

High-pressure technology - Water filter

In optimum position and easy to clean: the standard water inlet filter - protects the large volume piston pump against gross contamination. (starting from MBHST1260)

High-pressure technology - Machine cleaning

The frequency-controlled professional high-pressure cleaners make it possible to clean machines with two persons at the same time - users can flexibly select between different washing performances and pressures.

High-pressure technology - Pressure control lance

Pressure control lances make cleaning with frequency controlled high-pressure cleaners even more flexible - water output and pressure are variably adjustable.

High-pressure technology - Safe hose guide

The safe and elaborated hose guide of the hose reel HST - protects the user against wires inside the high-pressure hose material and ensures clean reeling up.

High-pressure technology - MBHot for subcontractor station

Robust 80 kW heating unit with large 3/8 heating coil - provides powerful heating of large water volumes and high performance of subcontractor unit.

Technical Data

More information

Service & Product inquiry

Would you like information material or a non-binding offer? We are looking forward to your inquiry!