Stationary Disinfection Gate 500

Vehicle decontamination on highest level.

Stationary disinfection gate with highest stability and automation.

The decontamination of incoming and outgoing vehicles is an indispensable component of operational hygiene measures, not only in the event of an epidemic or for African Swine Fever prevention. The pathogens are exchanged and spread, particularly at logistic intersections with livestock transports and companies supplying raw materials.

The disinfection gate DESTOR ST500 operates fully automatically, without man-power, thus ensuring a high level of safety and reliability. An electric dosing pump mixes the disinfectant solution, the high-efficiency sensors trigger the nozzles and a high-performance pump guarantees the required application of disinfectant.

Safe disinfection with fully automatic operation.

The vehicle lock works constantly and reliably at the specified concentration of the disinfectant solution. The three-dimensionally spray nozzles are not susceptible to wind and guarantee a spread rate of 0.4 litres per square metre at a passage speed of 2.4 km/h. Offset arranged nozzles in the archway moisten the vehicle from above and from all sides. Full-surface wetting is guaranteed for all vehicle sizes, from passenger cars to drawbar combination trucks. The powerful nozzles in the floor ramp ensure particularly intensive underbody, tyre and wheel case wetting.

As soon as the vehicle approaches the disinfection arch, the high-efficiency sensors start the pump. The nozzles distribute the disinfectant directly at full and constant pressure, also from the front and rear and between the bodies.

Overview of stationary and mobile disinfection gates

The overview of the Meier-Brakenberg disinfection gate variants: from the basic equipment with tubular frame, disinfection pump and hand transmitter to the complete, mobile solution including automatic dosing and start/stop function.

- Mobile disinfection arch DESTORmobil500

- Stationary disinfection gate 500 with robust 4-sided tubular frame and complete equipment

- Stationary disinfection gates 100 & 200 with basic equipment and expansion options

Product Details

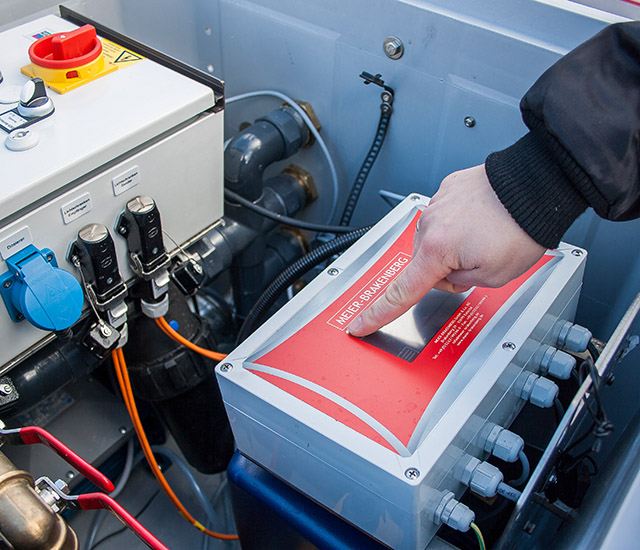

DESTOR ST500 – Control container

Container for safe storage of the stainless steel centrifugal pump, control and metering unit as well as drive-through sensors.

DESTOR ST500 – Storage tank

1000 litre capacity for mixed solution with floater-controlled automatic refill, all connections available.

DESTOR ST500 – Underbody disinfection

Underbody disinfection with nozzle line in a two-part drive-over ramp over a width of 3.15 m. Safe decontamination of tyres and wheel housings.

DESTOR ST500 – High-efficiency sensors

Equipped with high-efficiency sensors, the system switches on fully automatically and on time and therefore ensures the complete spraying of the truck from all sides.

DESTOR ST500 - Sensor drive-through control

Programmable sensor circuit for passing through the disinfection lock in one or both directions

Technical Data

| Spray arch | Aluminium profile construction, internal nozzle train with immediate stop nozzles, 3.52 m wide floor truss with recessed nozzles, passage dimensions 3.64 x 4.58 m (w x h), external dimensions 5.52 x 4.78 m (W x H) |

| Pump and control unit | High performance chemical centrifugal pump 200 l/min, 230 V/50 Hz, 1.85 kw, hoses and couplings |

| Electronic injection doser with stepper motor pump: flow rate 10-2,500 l/h, dosing 0.01-15 %, max. 30 l/h, batch and time dosing function | |

| Documentation option, dimensions box 0.80 x 1.38 x 1.05 m (l x w x h) | |

| Solvent storage tank | 1000 l plastic container with fork lift attachment, suction basket and ventilation device, floater control |

| Dimensions tank 1.00 x 1.20 x 1.50 m (l x w x h) |

More information

Service & Product inquiry

Would you like information material or a non-binding offer? We are looking forward to your inquiry!