Stationary Disinfection Gate 200

Automatic decontamination lock for vehicles of all kind.

This vehicle lock is always in use to protect your business!

With the disinfection gate at the farm borders, everyone can protect their own animal population from the introduction of diseases. Similarly, vehicle decontamination can prevent the spread of epidemics and diseases in production or processing operations such as slaughterhouses, animal processing plants, feed plants, grain stores and other upstream or downstream areas. This protects the company's own operations and those of its customers. All vehicle types and sizes can be fully wetted and disinfected with the DESTOR ST 200 drive-through lock.

Safe hygiene, even when you are not on site.

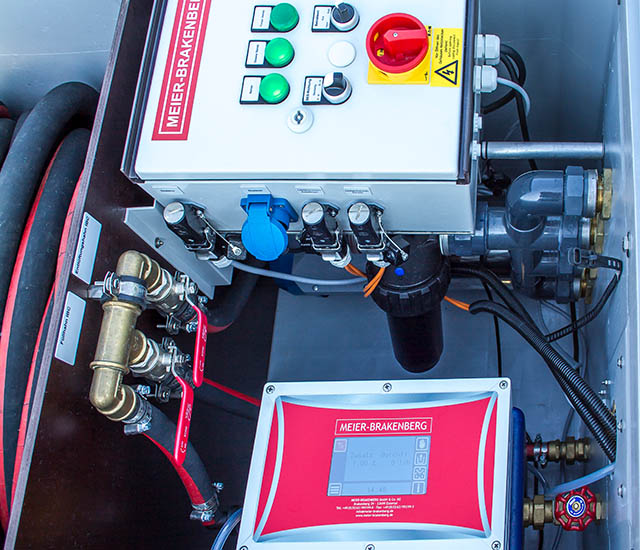

The disinfection gate is installed on a steel collecting pan or on a concrete floor with a collecting device. The pump and control equipment is mounted in a weatherproof control container on which all water connections are already installed.

The decontamination solution is provided by a buffer tank. You can mix it yourself or optionally it can be provided by a dosing pump in a reliable concentration. The disinfection lock is put into operation on the control unit and then, thanks to sensor recognition, the entire decontamination process runs fully automatically. The sensor system detects entering vehicles and triggers the pump. The spread rate of 0.4 litres per square metre is guaranteed by the pump performance at a travel speed of 2.4 km/h.

The floor traverse with integrated nozzles ensures safe underbody, tyre and wheel case wetting. The arrangement of the nozzles on the arch and the sensitive sensors ensure that the entire surface of the vehicle, including the front and rear, is wetted.

Performance in detail:

- The gate can be mounted on concrete floors with a collecting device or on a steel pan.

- The spray arch consists of a sturdy stainless steel tubular frame with integrated wind-resistant nozzles.

- The arch is stiffened with corner and foot brackets on both sides for stabilisation.

- High-efficiency sensors for the automatic drive-through system are attached to the archway. It has an adjustment option and allows either one-sided or double-sided triggering of the spraying device.

- Constant pressure on the nozzles is generated by a multistage stainless steel centrifugal pump with 200 l/min.

- The technology is safely accommodated in the pump and control box. Optionally, the dosing technology can also be installed here.

- Note: complete disinfection of vehicles is only possible with mounted floor nozzles, see optional equipment.

Optional Equipment:

- Drive-over ramp MBDEST028: Double aluminium floor ramp, 80 cm wide, with floor nozzle string. Laterally and horizontally offset arranged nozzles allow intensive wetting of the underbody area. Dimensions: ramps twice 800 x 750 x 88 mm.

- Drive-over ramp MBDEST029: Hot-dip galvanized steel ramp, 3.52 m wide, with floor nozzle strand. Nozzles offset laterally and horizontally allow intensive wetting of the underbody area. Dimensions: 0.82 x 3.52 x 0.07 m

- Drive-over ramp MBDEST029-02: Stainless steel ramp, 3.52 m wide, with floor nozzle strand. Nozzles offset laterally and horizontally allow intensive wetting of the underbody area, dimensions: 0.82 x 3.52 x 0.07 m

Highest Operating Comfort:

- Solution tank MBDEST018: Container for mixed disinfectant solution, 1,000 litre plastic container with float switch, connection and ventilation set as well as suction hose.

- Collecting pan MBW2000: Two-piece steel drip pan, primed and painted, dimensions 3.81 x 4.30 x 0.07 m

- Collecting pan MBW1000 Longlife: Mobile disinfection and collection pan made of particularly tear-resistant polyester fabric, coated on both sides, lateral upturns, entry and exit side with flexible foam core, dimensions: 20.00 x 3.60 m

- Dosing technology MBDEST034: Automatic filling system for the solvent container. Exact dosing of liquid products in a setting range of 0.01-15 %. Water consumption measurement and documentation via SD card. Integrated in pump and control box, dimensions: 0.80 x 1.38 x 1.05 m.

Product Details

DESTOR ST200 – Underbody disinfection

Two drive-on floor ramps for powerful underbody, tyre and wheel case cleaning via nozzle line.

DESTOR ST200 – Pump and control box

Container for safe, protected storage of the pump, sensor control and, if necessary, the metering unit.

DESTOR ST200 - Sensor drive-through control

Programmable sensor circuit for one- and two-sided triggering of the disinfection lock.

DESTOR ST200 – Wind resistant nozzles

Strong three-dimensional spray mist is applied to the entire surface of the vehicle.

Technical Data

| Spray arch | 50 mm stainless steel tubular frame with 2 corner consoles at the top and 2 floor consoles |

| Inner dimensions 3.68 x 4.55 m (w x h) | |

| Pump and control unit | With lid, dimensions 0.80 x 1.38 x 1.05 m (l x w x h) |

| Drive-through control: high-efficiency sensors for one-sided or two-sided traffic | |

| Pump: multistage stainless steel centrifugal pump 200 l/min, 230 V/50 Hz, 1.85 kW |

More information

Service & Product inquiry

Would you like information material or a non-binding offer? We are looking forward to your inquiry!