High pressure cooling system dairy cattle

Cooling against heat stress in dairy cattle farming.

Heat stress for cows begins at around 20 °C and leads to lower fertility due to metabolic stress. Feed intake is reduced by 10 to 20%, resulting in lower milk yield. Cooling inside the dairy cattle building is important for the well-being of the animals. An efficient high-pressure cooling system is capable of increasing the animals’ performance. It can be installed above the walkway and/or in the waiting area, wetting of the animals is avoided.

Cooling for best possible climate.

Our high-pressure cooling system works according to the principle of direct evaporative cooling. High-pressure nozzles atomize water at a pressure of 70 bar and supply the stable air with mist. The water mist then immediately vaporizes and withdraws thermal energy from the air at the same time. Due to the high pressure and the very fine mist it is possible to quickly and effectively cool down the air by 5 to 10 °C without causing any wet conditions.

Additionally, high-pressure cooling can also be used for dust binding.

For cool calculators.

- Economic high-pressure cooling system

- Full-fledged air cooling system complying with Animal Welfare criteria

- Dust binding via special dust binding control program

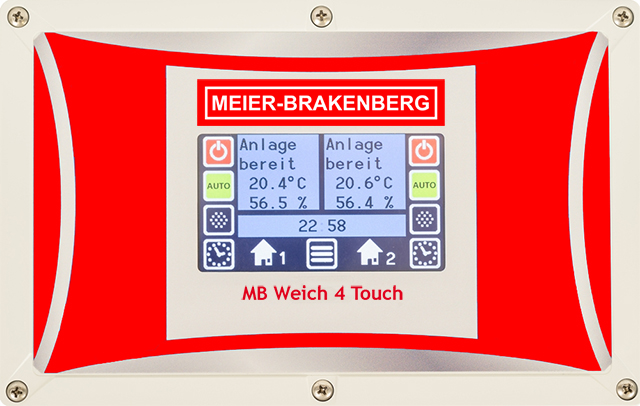

- Easy to operate and menu-driven cooling control MBWeich4

- Temperature sensor and humidity-dependent control as standard.

- Integrated pressure release for strict observance of spraying intervals

- Top-quality high-grade steel cooling nozzles, welded to the stainless steel pipe > Durability and maintenance-free operation

- 4-fold filter units

- Fully automatic operation in several buildings possible, central installation of control unit

- Individual planning and design for any stable

- Easy self-installation, on request complete assembly or supervised installation

Product Details

High-pressure cooling - Pump station

The centerpiece of high-pressure cooling unit: 70 bar plunger pump with low-speed electric motor.

High-pressure cooling system - Filter unit

Quadruple filter unit with coarse and fine filters - space saving mounting to wall with the help of a holding frame.

High-pressure cooling - Atomizing nozzle

High-pressure cooling nozzles made of high-grade steel generate very fine water mist which evaporates and brings about a cooling effect within in a very short time.

High-pressure cooling - Nozzle branch

High-pressure cooling nozzles made of high-grade steel - mounted inside a stainless steel pipe: no corrosion, no wear and tear.

High-pressure cooling - Nozzle branch

Stainless steel pipe and stainless steel nozzles.

High-pressure cooling - Pump station

Central installation enables supply of several buildings.

Technical Data

More information

Service & Product inquiry

Would you like information material or a non-binding offer? We are looking forward to your inquiry!